Product designs change as the years pass, and a company may finally need to rethink their entire manufacturing process. Older machines may need continuous maintenance, or they could just be inefficient due to lack of elements not available when they were created. When it is time to retool, the entire plant may be shut down. This is to avoid injuries to workers, make the process of changing the building more efficient, and it can be helpful when moving new machinery into its designated space. All of this takes planning, but a good retool of a plant can make a manufacturing process much more economical.

Safety Considerations

It is a fact that safety is an overriding concern in manufacturing processes. Many machines are loud, the workers wear headphones that cancel out the noise, and they must focus on the job. Trying to do their jobs while old machinery is being moved out and new machines are coming in could present safety issues. This is one of the reasons most plants close completely during retooling. One more concern is getting the work done on a schedule. If the crew doing the work does not have to work around manufacturing processes, then they are generally able to keep their own schedule on track.

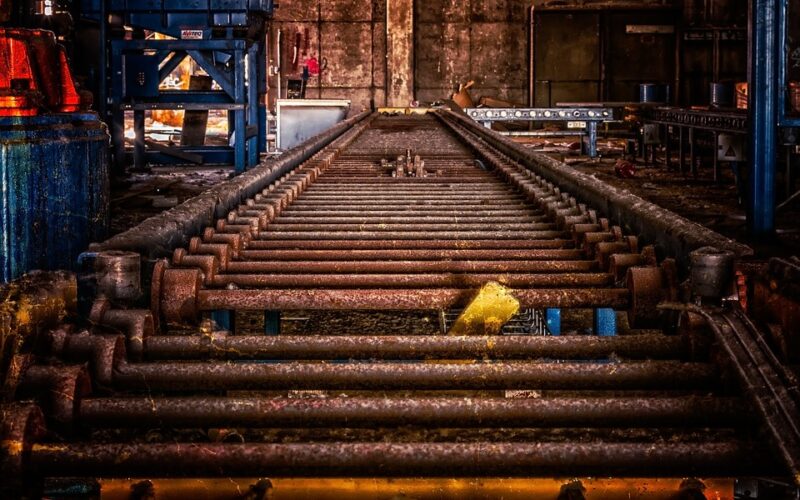

A New Design

Machinery made years or decades ago might be much larger or smaller than new machines performing almost the same function. They could have different requirements for loading raw materials or taking out finished products. That factor could make it a good idea to consider a new design for an entire plant. An empty building with the machines removed could undergo a complete gutting of the interior as new flooring, partitions, and machinery are about to be installed. Modernization can be expensive, but it can save once the new processes and machines are up and running again.

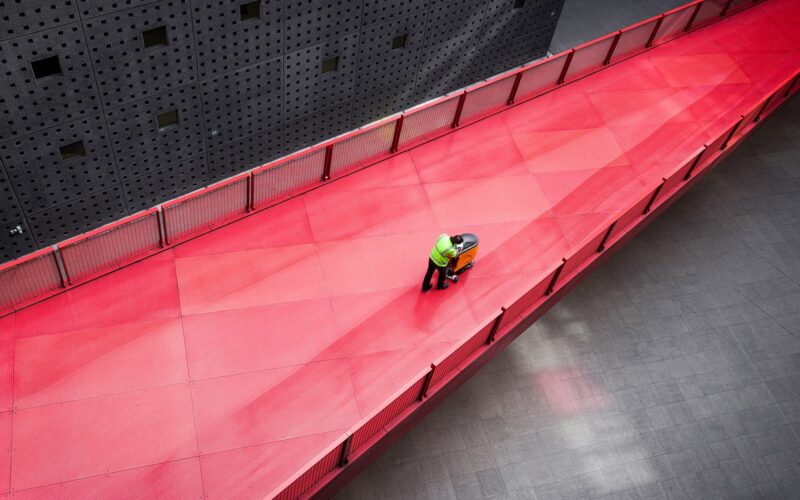

An Efficient Environment

The main focus of many during a retooling might be the machinery, but there are other areas that could use some improvement. Flooring might be worn out in heavy traffic areas, or a flooring design that helps workers move materials more efficiently could be a necessity. Companies completely redesigning their plants may turn to Pennine Aggregates to help them create flooring that will make a positive impact. They have a range of different sizes and colours of dried aggregates that are ready to be used to create floors made of resin bonded aggregates. One of the main reasons to use resin bound aggregates in flooring is due to their long wear life, yet the colours can be used to indicate specific pathways for raw or finished materials.

The work of modernizing a manufacturing facility is a complex one. There are many factors to consider during the planning phase. Putting those plans into motion may take shutting down a plant for a few weeks or months, yet the end result could be a better bottom line. While few companies are eager to retool their entire plant, it could be a positive step forward for their workers, their products, and their bottom line.